CO2 transport and storage: This is how it is done

For some industries the technologies are not yet available to make the full transition to a sustainable production process. We can help by collecting and storing their CO2 safely in empty offshore gas fields. Here's how we do it.

We collect

We collect, in barges, the CO2 that is captured from your production process:

- Industrial partners with CO2 capture installations

- Collection at customer site or at pipeline terminal

- Multiple customers can be serviced

Liquefaction

- Modular Compression Conditioning and Liquefaction system

- Quayside required for barge access

- Our partner:

We store safely

We store your CO2 safely by directly injecting it in empty offshore gas fields*:

- Collaboration with offshore operators

- Minimal offshore power requirements (hydraulics ESD)

- Multiple storage locations foreseen

Offshore Interface

- Direct injection, independent of onshore terminals and export pipeline infrastructure

- Offshore interface (TLU) re-deployable

- Short pipeline connection to wellhead platform / manifold

- Our partner:

*We can also deliver your CO2 to a user, who stores the CO2 in its products (CCU).

Full capacity design

Per customer we provide a minimum of 2 barges of 5500 cubic meters each, operated by pusher-tugs. That amounts to a scalable capacity starting at some 0.5 million tonnes per year up to multi-million tonnes per year per customer .

Operational from 2029

We are working with several operators to define in excess of 50 million tonnes of CO2 storage capacity in the Southern North Sea. Early 2021 we finished the detailed design and received Approval in Principle from Bureau Veritas. Construction of the first barge is expected to start in 2026-2027 and some two years later we will collect, transport and store the first CO2.

Flexible and rapidly available

Our flexible approach is probably the best option if your installation is not near an existing or planned CO2 pipeline. And even if you are near a planned pipeline, our method could be a more rapidly available alternative. You could be one of the first onboard, when we finish our first fleet in 2029.

2019: Zandguard Joins

Zandguard supports and joins Carbon Collectors

2021: Design Approval in Principle

Detailed design get Approval in Principle

2023: Partnership Baker Hughes

2024: Storage

Storage. Final agreement on first storage location.

2026-27: Build

Start construction.

2029: First fleet operational

Fleet operational for first 0,5-1,5 Mtpa project.

Scale up

Scale-up to 6 million tonnes per year

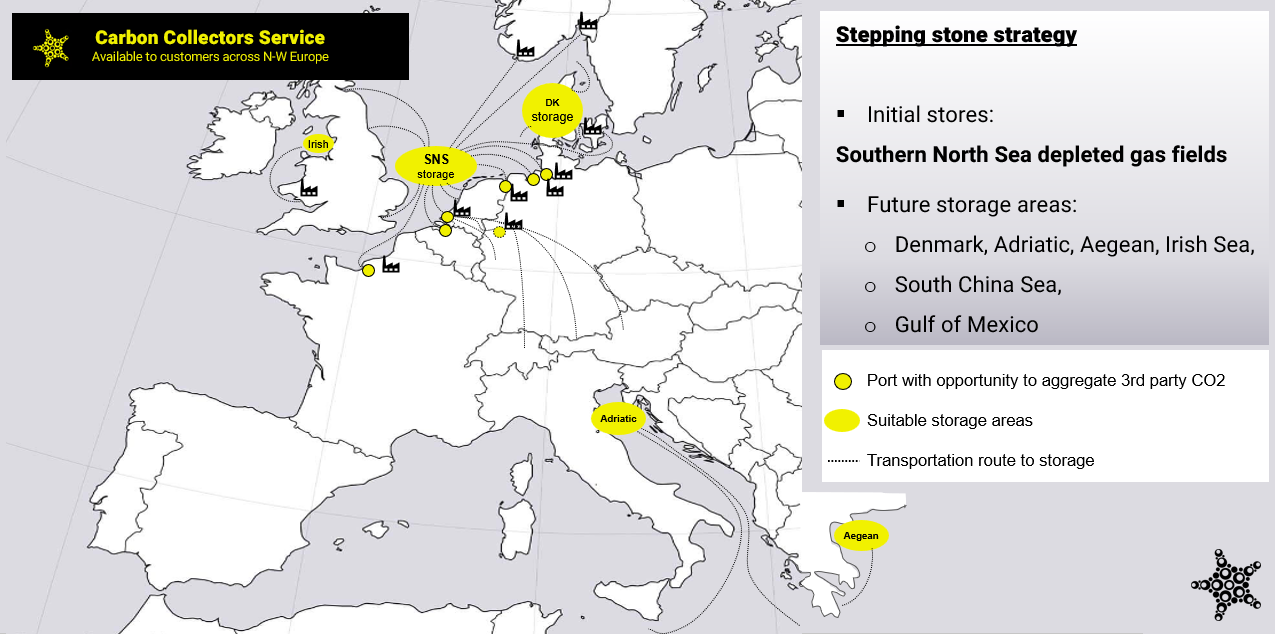

CO2 Storage Areas

We follow a stepping stone strategy, transporting our first CO2 cargo to a depleted natural gas field in the Southern North Sea while preparing to expand to other sectors of the North Sea as soon as these become available. By the early 2030's we plan to build a network of customers and storage locations that will allow us to transport CO2 from almost anywhere in Western Europe to the nearest storage location or port-based user.

HEADQUARTERS

Carbon Collectors

Leonard Springerlaan 35

9727KB Groningen

The Netherlands